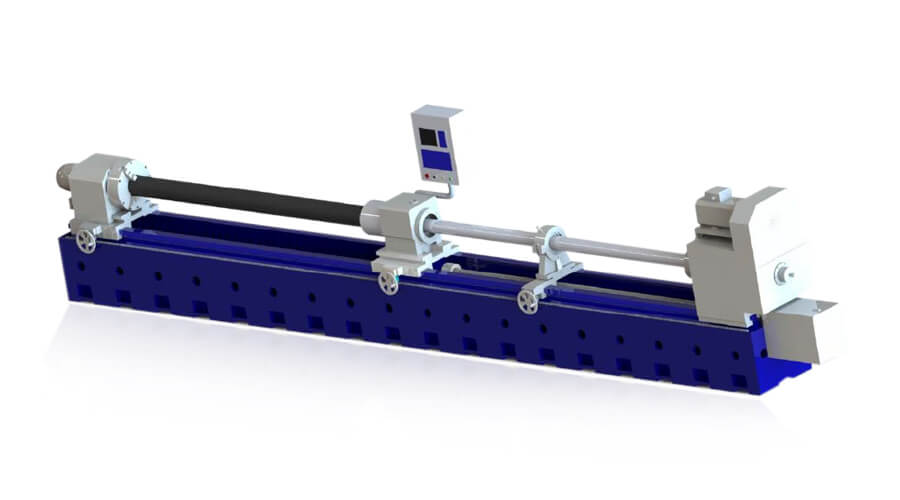

Boring, Skiving & Burnishing Machine

Product Introduction

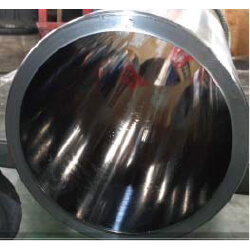

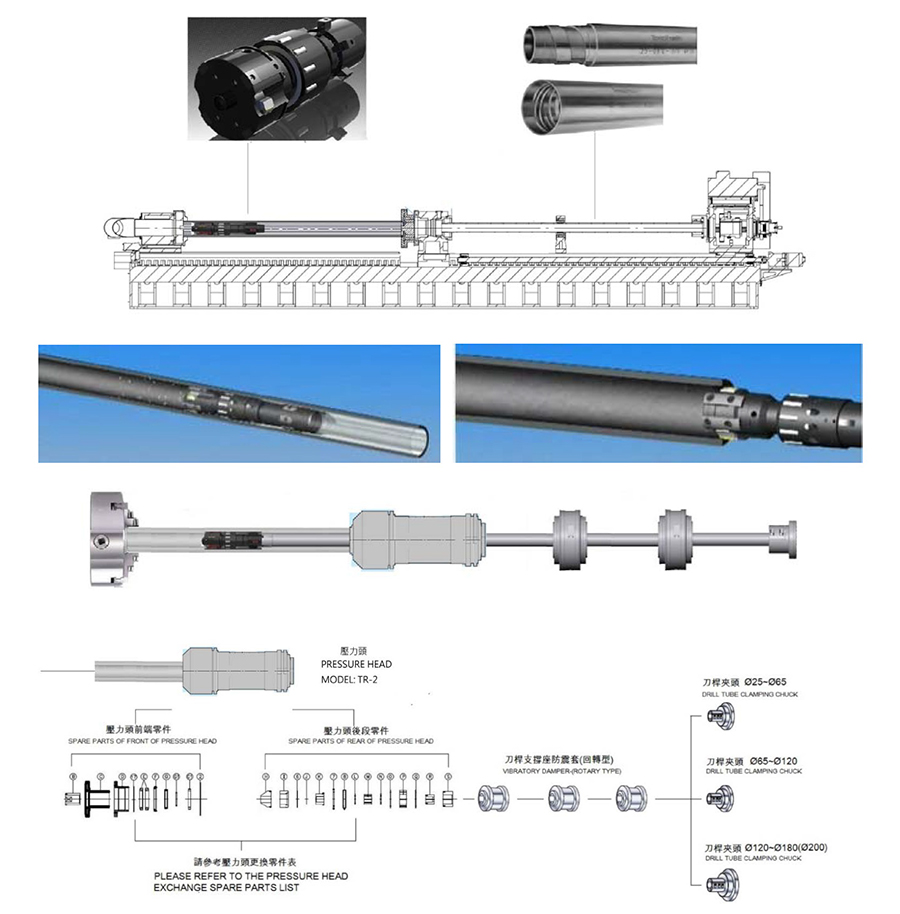

The BTA skiving and roller burnishing machine is primarily used for precision reaming and roller burnishing processes on hollow/hydraulic cylinders after deep hole drilling or cold drawing. The machining accuracy can reach H7, and the surface roughness can achieve Ra.0.1μm. Microdrilling skiving roller burnishing machines can improve or replace the grinding marks on the surface left after honing and grinding processes.

- S-series deep hole Skiving and Roller Burnishing Machine is used to boring and roller burnish the workpiece at the same time. The main advantages are high processing efficiency, stable performance, simple operation, overall beautiful appearance, and good design of anti-spatter set to prevent the leakage of Coolant.

- The processing of this machine is the combination of the fixed workpiece, rotation of the tool, skiving and roller burnishing tool, which effectively solves the problems of the traditional deep-hole drilling of hot-rolled steel pipe and cold-drawn steel pipe. The drilling precision can reach IT7 IT8 with the highest surface roughness that can reach precision Ra0.2 Ra0.4

- The machine can be equipped with PLC + man-machine interface or FANUC, Mitsubishi, and Siemens CNC control system, A/C spindle motor, and inverter drive. Headstock is designed as a 2-step speed changes gearbox to increase the spindle torque and make invariable speed possible.

| Description | S-100 | S-150 | S-200 |

|---|---|---|---|

| Max. dia of Skiving & Burnishing | Ø38- Ø100 mm | Ø50- Ø150 mm | Ø50- Ø200 mm |

| Max. Depth (Z axis) | 1000/2000 mm |

1000/2000/3000/4000/5000/6000 mm | 1000/2000/3000/4000/5000/6000 mm |

| Drilling spindle head motor | 30 kw | 40 kw | 40~50 kw |

| Drilling spindle feed (Z) | 4kw with 1:10 Gear Box | 4kw with 1:10 Gear Box | 7kw with 1:10 Gear Box |

| Coolant pump motor | 7kw with 1:10 Gear Box | 10 kw + 7.5kw | 10 kw + 7.5kw |

| Range of spindle speed | 200~2000 rpm | 150~1500 rpm | 120~1200 rpm |

| Drill Speed | 1~200 mm/min | 1~200 mm/min | 1~200 mm/min |

| Rapid | 4000 mm/min | 4000 mm/min | 4000 mm/min |

| Ball screw of Z-Axis | Ø80 x P10 | Ø80 x P10 | Ø80 x P10 |

| Width and box way of bed | 580 mm | 800 mm | 800 mm |

| Controller | Fanuc, Mitsubishi, and Siemens | Fanuc, Mitsubishi, and Siemens | Fanuc, Mitsubishi, and Siemens |

| STANDARD ACCESSORIES | OPTIONAL ACCESSORIES |

|

|